Mute Wire Terminal Crimping Machine of Terminal Crimping Applicators Wire Cable Terminal Press Machine

Basic Info.

| Model NO. | 2T |

| Motor Power | 750W-3000W |

| Working Voltage | 220V |

| Applicable Mold | Horizontal Mold(Optional) |

| Trip | 30mm |

| Crimping Force | 2.0-8.0t |

| Function | Auto Feeding Terminal, Crimping |

| Transport Package | Plywood Case |

| Specification | 34*22*64cm |

| Trademark | Sinrad |

| Origin | China |

| HS Code | 8479819000 |

| Production Capacity | 100 Sets/Month |

Product Description

Mute Terminal Machine IntroductionThe mute terminal machine is a high-speed automatic terminal machine, which can be replaced by a card-type die. The machine is easy to operate and easy to maintain. It is designed for high-yield and low-maintenance manufacturers to save the cost of waste during the failure period. The appearance is beautiful and elegant, which makes the factory more advanced.

Mute terminal model ultra-quiet terminal machine, using high-tech frequency conversion technology; electronic accurate positioning; motor working noise is smaller than traditional terminal machine when crimping, and power saving; mold adjustment is more convenient and faster; avoid traditional terminal clutch, electromagnet And other common faults!

Feature

1. Replaceable direct delivery mold, cross feeding mold, single terminal mold

2. The voltage is stable and the speed is high.

3. Computer terminal DC terminal Single terminal With terminal

4. Lightweight structure Easy to move the workplace, the operation sound is small.

Type of Mute Terminal Machine Type

All the standard crimping machines are with 30mm stoke, applicable for OTP type applicator. Can modify to 40mm, and with the install head&base to applicable for European type applicator.

| item | 2T Muti terminal machine | 3T Muti terminal machine | 4T Muti terminal machine | 6T Muti terminal machine | 8T Muti terminal machine |

| force | 2T | 3T | 4T | 6T | 8T |

| power | 750W | 1100W | 1800W | 2200W | 3000W |

| body thickness | 14mm | 16mm | 20mm | 25mm | 30mm |

| weight | 47kg | 52kg | 85kg | 115kg | 124kg |

| size | 34*22*64cm | 34*22*64cm | 31*26*72 | 29*36*81 | 29*36*81 |

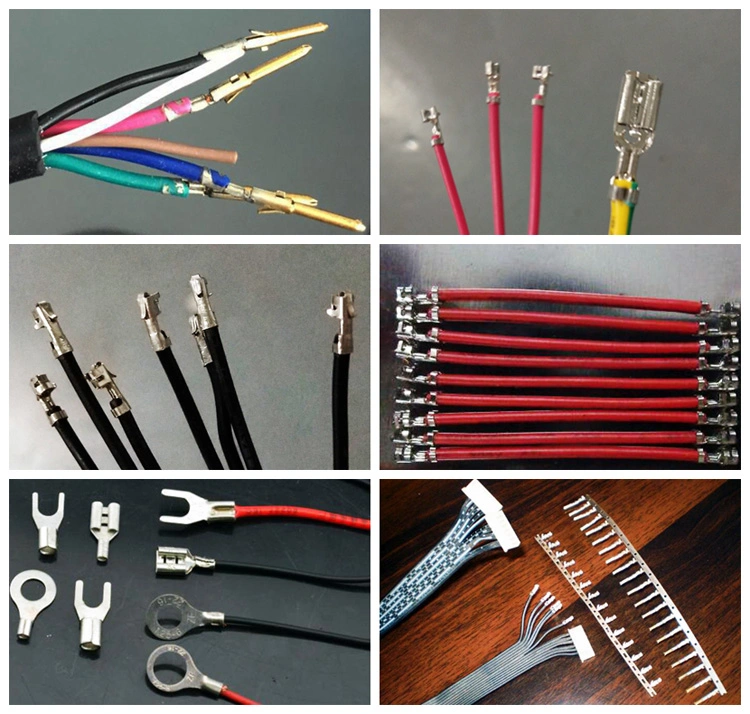

Application

Applicator

Various terminal machines and copper belt machines can be used to press the mold according to customer requirements. Stable mold performance, high precision and affordable price. Note: Each set of molds is equipped with a set of blades (according to customer terminal products). Can be combined with / scattered, customized die according to different needs.

OTP horizontal mold The most commonly used mold in the wire harness processing industry has the advantage of easy feeding and debugging. And the number of blades is small, easy to install. Equipped with two scale knobs, you can easily adjust the blade.OTP straight mold The blade of a straight mold is usually composed of more than six blades, four of which are conventional blades for riveting the core wire and the outer cover, and the other two are used to cut the tape.

2000 type mold Type 2000 molds are widely used, and can be equipped with horizontal, direct, single and flag terminals. Suitable for 110/187/205/250 flag terminals, true flag terminals, false flag terminals and other products.

OTP single grain mold The simplest kind of mold is especially used for crimping single terminal. Commonly used for single-grain pre-insulated terminals, ground terminals, spring plug terminals, etc. The installation and commissioning are extremely simple, especially suitable for novice users.

| Contact: |

We can customize All kind of applicator for you.

You just your product photo for reference and contact us.

Sinrad Technology Co., Ltd

sinrad.en.made-in-china.com

sinrad.en.made-in-china.com

E-mail:[email protected]

| FAQ: |

1 Price terms

The price is based on EWX/FOB, if you request CFR or CIF, please give us your delivery port, and we will give you CFR price or CIF price for reference.

2 Can I send samples to check the machine quality.

Yes, welcome to send us samples. We would be pleased to show you trial testing base on your samples.

3 How to learn the machine?

1) Offer free technology learning support in our factory

2) Provide detail user manual with detail video illustration

3) Support engineer service at site if clients asking for

4 How about the lead time and delivery time of order?

Standard model, can be ship out within 3~7days after confirmed order and deposit.

Customized model, normally lead time is 10~30 days, after confirmed all order detail deposit and got samples.

| Company info: |

Sinrad Technology Co.,Ltd, specialized in automation machine, customizing and manufacturing cable processing(cutting, striping, twisting, crimping, soldering, housing inserting, winding, binding, testing, etc.) machine, automatic soldering machine, intelligent soldering machine, and other production equipment.